Manufacturing

Type of mixed feed

Shrimp pellets

Shrimp pellets are a solid feed for shrimp molded by Higashimaru's unique manufacturing method. We have a variety of pellets available in different sizes to suit shrimp growth, as well as regular products, high-quality feed, low-cost feed, and infection-control feed.

EP(extruded pellet)

Extruded pellets are solid feeds formed by high-temperature and high-pressure processing in an extruder. From initial to finishing feeds, this feed can accommodate a variety of fish species and a wide range of fish sizes. The amount of oil and fat added and particle size can be adjusted broadly, and floating and sinking feeds can also be adapted to provide feed that meets our customer's needs.

DP(dry pellet)

Dry pellets are a solid feed formed by a pellet machine. The uneven grain length allows for efficient feeding according to the size of the fish to be raised. Our unique manufacturing process reduces powdering and water pollution, making the feed environmentally friendly.

Mash

Mash is a powdered feed made by grinding raw materials into a powder. They are used as moist pellets mixed with water, oil, raw feed, etc., and as dough-type feed for eels. We can accommodate particle size and blending to meet the customer's needs.

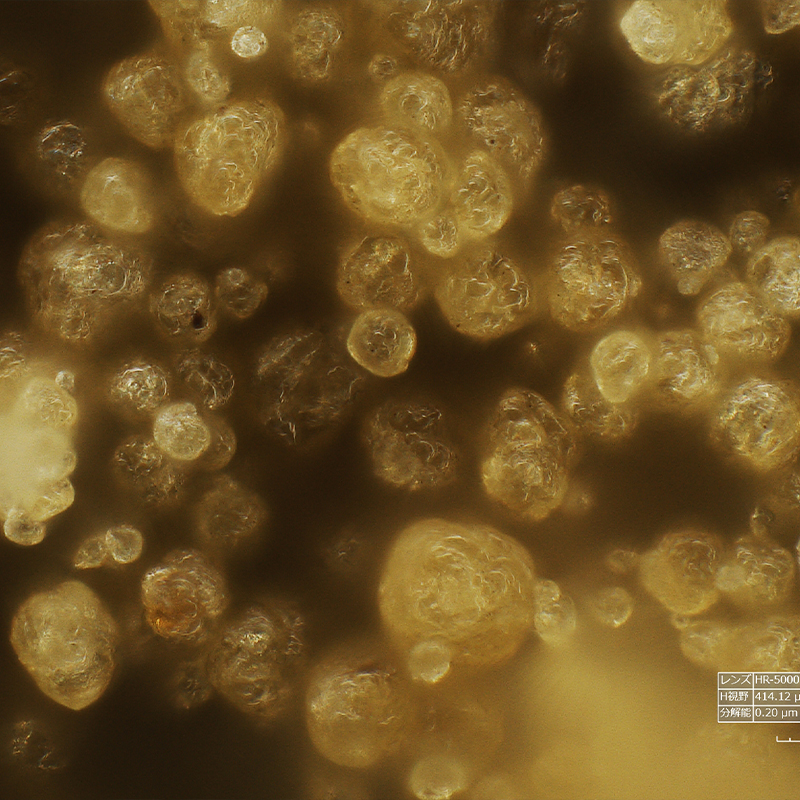

Microcapsule

Microcapsule is a type of feed developed with new technology. It is a fine-particle initial feed with excellent uniformity of nutrients, elution control effect, and dispersibility in water. It is expected to have exceptional nurturing effects by suppressing water quality deterioration from feeding.

Feed for larval shrimp and juvenile fish

Feed from larval shrimp and juvenile fish is made from powdered raw materials in granule form using a unique granulation process or from pellets grounded into powder or crumble form. It is highly palatable, nutritious, digestible, and highly regarded for growth.

Providing safe and reliable products

Fishmeal, wheat flour, soybean meal, and many other ingredients that are the main raw materials of today's mixed feeds for fish farming are of natural origin.

They are greatly affected by the hectic environmental changes in the world.

To provide customers with safe and reliable products under any circumstances, we realize safety and reliability through thorough quality control.

Higashimaru Fisheries Division has acquired ISO 22000 certification in 2020.

We are dedicated to ensuring a safe and reliable production system by implementing comprehensive process control in accordance with the ISO system.

Raw material inspection and analysis

Raw materials are visually and sensory inspected for color, odor, etc., followed by component inspections. We check the safety and component values against analysis certificates and specifications provided by raw material suppliers.

Sample physical properties/composition test

We inspect the physical properties and composition of the finished product. Items checked include grain size, hardness, floating capability, specific weight, water absorption level, moisture, crude protein, crude fat, and crude ash. After inspecting these items, we deliver safe and reliable products to our customers.

stable automated production

By conducting computerized process control, our products are automatically produced reliably and stability, from raw material input to finished products.

storage and management

Manufactured products are stored by date of manufacture and brand name until shipment.

Environmental Efforts

Higashimaru Co., LTD. supports the SDGs and is committed to contributing to the achievement of the SDGs.

We collect odors generated at our feed mills using deodorization equipment and strictly adhere to the regulatory limits while considering the environment.

Deodorization equipment is installed to remove odors generated during the aqua feed manufacturing process. In addition, we endeavor to protect the environment in the surrounding area by regularly measuring odors and keeping them below standard values.

We will aggregate the energy intensity of the Kagoshima factory to improve the efficiency of feed production.

Energy intensity is aggregated to determine which processes use the most energy, to get a clear picture of energy use in the factory, and to explore effective improvement measures to reduce CO2.

*Energy intensity: an indicator of how efficiently energy is used in production.

We will work to conserve electricity and protect the environment at all of our facilities.

We are working to conserve the environment by switching to LED lighting, optimizing brightness, and introducing automatic light-on/light-off systems to implement lighting measures to save electricity, improve energy use efficiency at our factories, and reduce CO2 emissions.

We are working on developing fine particle starter feed (microencapsulation) that will control the deterioration of water quality.

Contact

お問い合わせ- 株式会社ヒガシマル

(HIGASHIMARU CO.,LTD.) - 〒899-2594 鹿児島県日置市伊集院町猪鹿倉20番地

- 管理部TEL:099-273-3859 FAX:099-273-6968

- 飼料営業部TEL:099-273-2538 FAX:099-273-3863

- 食品営業部TEL:099-273-4653 FAX:099-273-3857